Introduction

In the realm of woodworking, the integration of technology has revolutionized the way artisans craft their creations. One such innovation is the Computer Numerical Control (CNC) router machine. These machines automate the woodworking process, providing precision and efficiency that traditional methods often lack. However, with a plethora of options available in the market, finding the best CNC for woodworking can be a daunting task. This guide aims to simplify the process by exploring key factors to consider when selecting a CNC router machine tailored for woodwork.

Understanding CNC Routers for Woodworking

What is a CNC Router Machine?

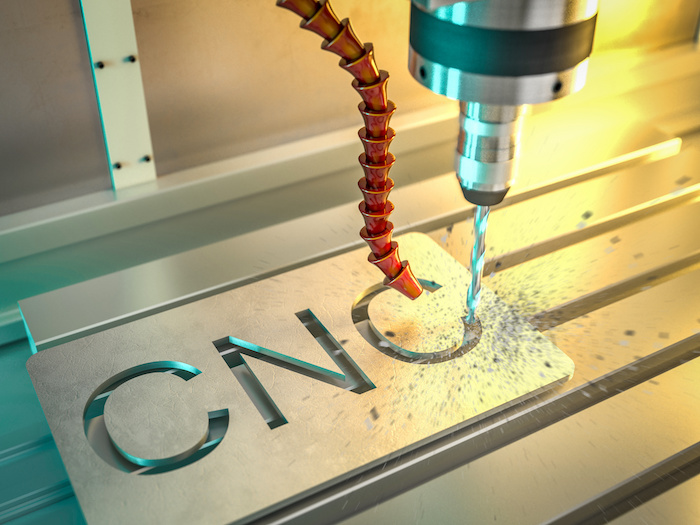

A CNC router machine is a computer-controlled cutting device that utilizes a rotating cutting tool to carve intricate designs into various materials, including wood, plastic, and metal. In woodworking, CNC routers are prized for their ability to execute precise cuts, intricate patterns, and complex shapes with consistent accuracy.

Importance of CNC Routers in Woodworking

CNC routers have significantly transformed woodworking practices by streamlining production processes and expanding design possibilities. Their versatility allows woodworkers to unleash their creativity, pushing the boundaries of traditional craftsmanship. Moreover, CNC routers enhance efficiency by reducing material wastage and minimizing human error, resulting in cost savings and increased productivity.

Key Considerations When Choosing the Best CNC for Woodworking

Precision and Accuracy

One of the primary factors to consider when selecting a CNC router for woodworking is its precision and accuracy. Opt for machines equipped with high-quality components, such as robust linear guides and precision ball screws, to ensure consistent and reliable performance. Additionally, look for models with advanced control systems and efficient spindle motors capable of delivering precise cuts across various wood densities and thicknesses.

Cutting Area and Bed Size

The cutting area, or bed size, of a CNC router determines the maximum dimensions of the workpiece it can accommodate. Evaluate your woodworking projects’ size requirements and select a machine with a cutting area that suits your needs. Consider factors such as the maximum width, length, and depth of the materials you intend to work with to ensure compatibility with the chosen CNC router.

Spindle Power and Speed

The spindle is the component responsible for rotating the cutting tool during the machining process. When choosing a CNC router for woodworking, pay attention to the spindle’s power and speed capabilities. Higher spindle power enables the machine to tackle tougher materials and perform deeper cuts, while variable speed control allows for optimal machining conditions based on the chosen material and cutting tool.

Software Compatibility and Ease of Use

The software interface plays a crucial role in operating a CNC router efficiently. Look for machines that are compatible with user-friendly CAD/CAM software, facilitating seamless design creation, toolpath generation, and machine control. Additionally, prioritize CNC routers with intuitive control interfaces and ergonomic features that simplify setup, operation, and maintenance, enabling woodworkers of all skill levels to harness the machine’s full potential.

Build Quality and Durability

Investing in a CNC router with a sturdy frame and durable construction ensures long-term reliability and performance. Evaluate the build quality of the machine, including the materials used, assembly methods, and overall rigidity. Choose reputable manufacturers known for producing high-quality CNC routers designed to withstand the rigors of continuous use in a woodworking environment.

Budget Considerations

While the temptation to opt for the most feature-rich CNC router may be strong, it’s essential to consider your budget constraints. Determine a realistic budget based on your woodworking needs and shop around for machines that offer the best value within your price range. Keep in mind that while costlier models may boast advanced features and capabilities, there are often more affordable options available that meet the requirements of hobbyists and small-scale woodworkers.

Conclusion

In conclusion, selecting the best CNC router for woodworking requires careful consideration of various factors, including precision, cutting area, spindle power, software compatibility, build quality, and budget. By prioritizing these key considerations and conducting thorough research, woodworkers can identify the ideal CNC router machine that aligns with their specific needs and enhances their craft. Embrace the transformative power of CNC technology and unlock a world of limitless creativity and precision in woodworking.